Business Overview

A recognized know-how in aircraft interiors design

Satys Cabin designs, manufactures and refurbishes aircraft interiors for aircraft manufacturers, airlines, corporate jets, and major OEMs across 3 sites in France and China.

Located at the Roissy-Charles de Gaulle Airport , in Toulouse and in China, Satys Cabin offers customers its expertise and know-how of complete interior systems from design to production. Its employs 210 highly skilled employees recognized for providing a range of products and services that include aircraft interiors as well as maintenance and high quality refurbishment services. I

Satys Cabin is able to design in all areas (mechanical, composite, electricity, water, air) using CATIA or NASTRAN software. It also ensures that tests are certified and carried out (fire, smoke, heat, and static, dynamic and decompression tests) and certifications (Minor and Major Mods, STC).

Satys Cabin works for Airbus Atlantic, Air France, Daher, Dassault Falcon Service, Royal Air Maroc, Sabena Technics et Airbus Interiors Services (AIS).

Key

Figures

Services

CORPORATE & VIP

CORPORATE & VIP

Refurbishment and completion with high skilled staff, and proven expertise

Airlines

Airlines

Unique interface for cabin modification including certification, design, production and support

OEM

OEM

Design and develop our own complex cabinets and monuments

Services

Services

Installation on aircraft or helicopter, snags management and on-site cabin works

Key Products

Lavatories

Front Row Monuments

Storages

Galleys

Partitions

Linings

Capabilities

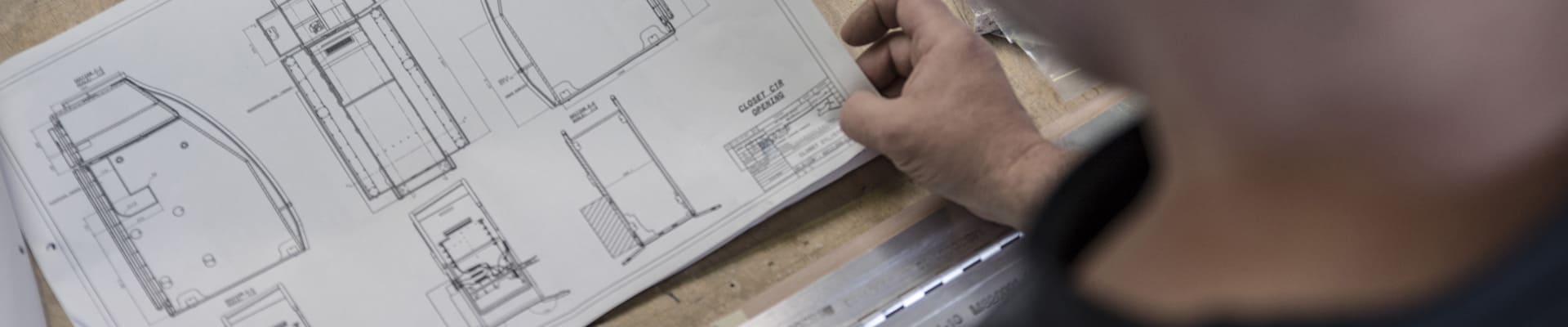

Engineering & Certification

Engineering

- Design

- Stress

- CMM, IPC

Certification

- Minor and Major modification

- LOPA change

- Seat modification under TSO

- Justification, certification documentation

- Structural test management (if required)

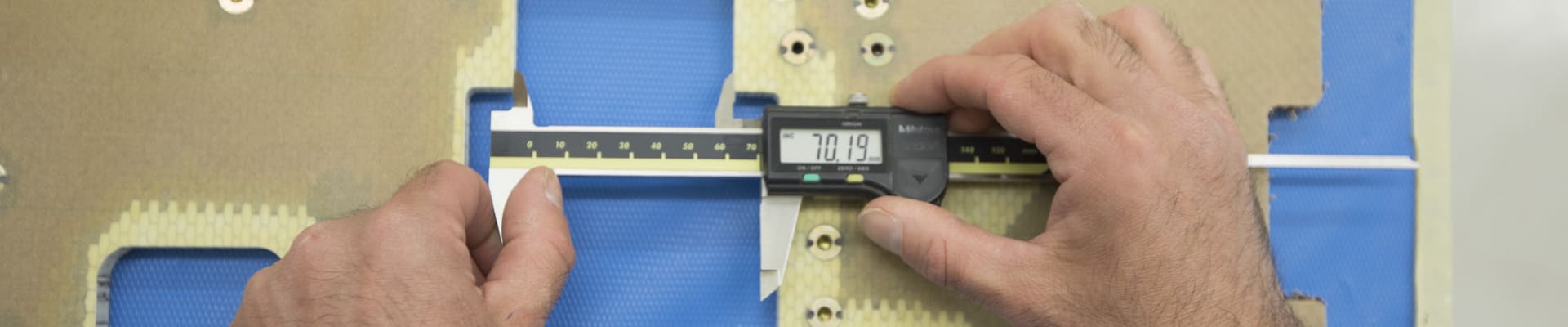

Production

- Manufacturing of sandwich composite panels

- Monuments Assembly

- Finish (tedlar, paint, laminate)

- Water system integration (installation & testing)

- Electrical system integration (installation & testing)

Maintenance & Services

- Monuments and Seats integration at Airbus Assembly Lines

- Support to OEM for Monuments finishing (touch-up, outlocated works)

- Dual release PART 145 & FAR

- Overall for cockpits seats with reduced TAT

- Lavatories Refurbishment