Business Overview

French leader of composite treatment.

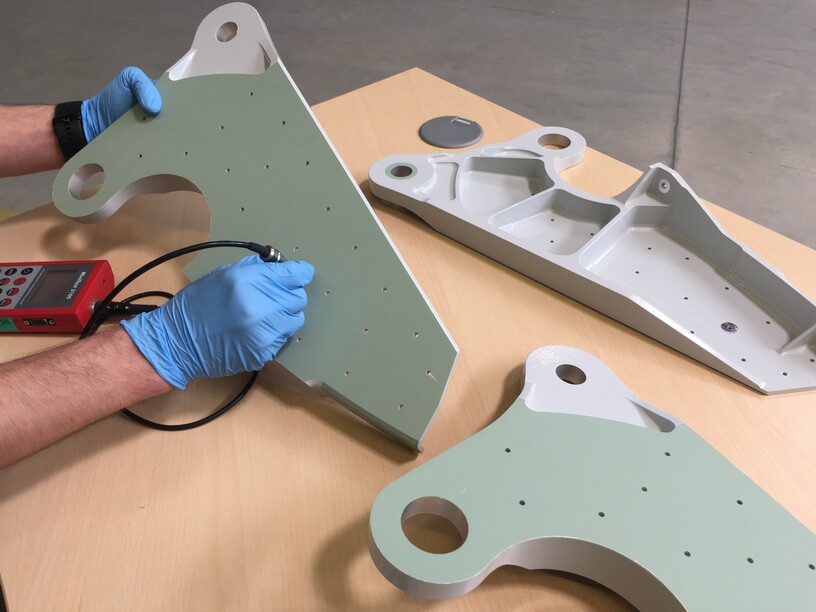

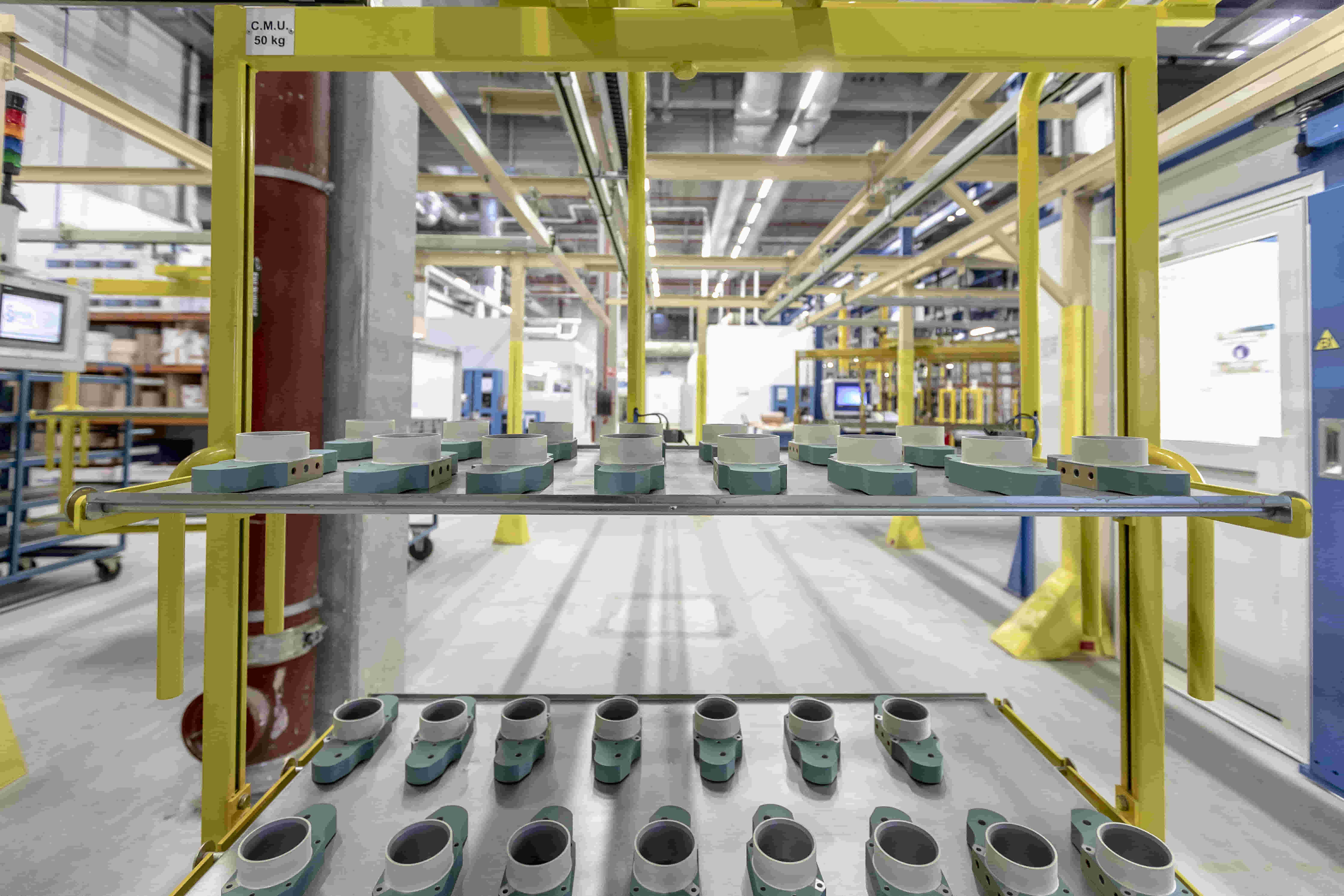

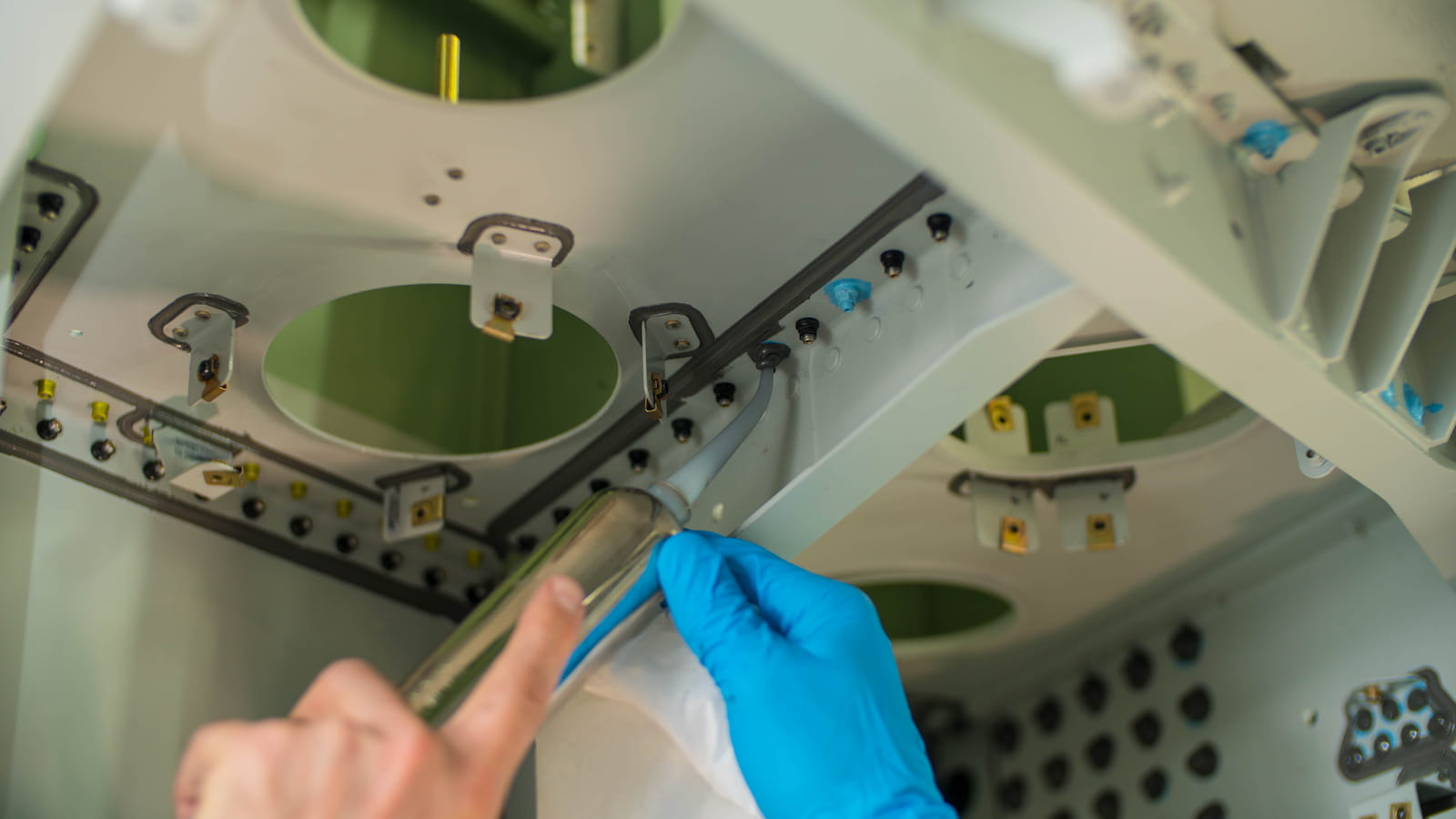

Satys Parts & Sub-assembly Protection was created following the acquisition and take-over of industrial sites and has more than 30 years of experience in this activity. It offers surface treatment, painting, adhesion promoting primer services as well non-destructive tests for metal and composite components for the aeronautics industry.

Satys Parts & Sub-assembly Protection division is located located near the airports of Bordeaux, Nantes, Casablanca, Tanger and Porto. It mainly works with Airbus, qu’Airbus Atlantic, Nexteam Group, Daher, Safran, Thalès et Lisi Aerospace.

Key

Figures

0

EMPLOYEES

0

PRODUCTION SITES IN FRANCE

0

PARTS/COMPONENTS PROCESSED PER YEAR

Markets

Aerostructures

Defence

Services

-

SURFACE PREPARATION

-

SURFACE PREPARATION

Sanding, Chemical pickling, Media-plastic

sanding, bead blasting, capping -

SURFACE PREPARATION

Sanding, Chemical pickling, Media-plastic

sanding, bead blasting, capping -

SURFACE PREPARATION

Sanding, Chemical pickling, Media-plastic

sanding, bead blasting, capping

-

-

SURFACE TREATMENT

-

SURFACE TREATMENT

- Aluminium

- Acid, alkaline, OASP, TSA pickling

- Stainless steel and titanium

- 120mesh blasting and media-plastic

- Fluo-nitric pickling / Nitric anodization

- Nitric passivation of stainless steel / Fluo-nitric conversion of Ti

- Steel

- Nickel-cobalt alloys

- Nickel and brass

-

SURFACE TREATMENT

- Aluminium

- Acid, alkaline, OASP, TSA pickling

- Stainless steel and titanium

- 120mesh blasting and media-plastic

- Fluo-nitric pickling / Nitric anodization

- Nitric passivation of stainless steel / Fluo-nitric conversion of Ti

- Steel

- Nickel-cobalt alloys

- Nickel and brass

-

SURFACE TREATMENT

- Aluminium

- Acid, alkaline, OASP, TSA pickling

- Stainless steel and titanium

- 120mesh blasting and media-plastic

- Fluo-nitric pickling / Nitric anodization

- Nitric passivation of stainless steel / Fluo-nitric conversion of Ti

- Steel

- Nickel-cobalt alloys

- Nickel and brass

-

SURFACE TREATMENT

- Aluminium

- Acid, alkaline, OASP, TSA pickling

- Stainless steel and titanium

- 120mesh blasting and media-plastic

- Fluo-nitric pickling / Nitric anodization

- Nitric passivation of stainless steel / Fluo-nitric conversion of Ti

- Steel

- Nickel-cobalt alloys

- Nickel and brass

-

SURFACE TREATMENT

- Aluminium

- Acid, alkaline, OASP, TSA pickling

- Stainless steel and titanium

- 120mesh blasting and media-plastic

- Fluo-nitric pickling / Nitric anodization

- Nitric passivation of stainless steel / Fluo-nitric conversion of Ti

- Steel

- Nickel-cobalt alloys

- Nickel and brass

-

-

PAINTING

-

PAINTING

- 93 + 7 paint booths and ovens

- 17 preparation rooms

- Liquid paint, powder paint, primer, finishing

- 17 preparation rooms

- Protective coatings

- Painting on metal and composite

-

PAINTING

- 93 + 7 paint booths and ovens

- 17 preparation rooms

- Liquid paint, powder paint, primer, finishing

- 17 preparation rooms

- Protective coatings

- Painting on metal and composite

-

PAINTING

- 93 + 7 paint booths and ovens

- 17 preparation rooms

- Liquid paint, powder paint, primer, finishing

- 17 preparation rooms

- Protective coatings

- Painting on metal and composite

-

PAINTING

- 93 + 7 paint booths and ovens

- 17 preparation rooms

- Liquid paint, powder paint, primer, finishing

- 17 preparation rooms

- Protective coatings

- Painting on metal and composite

-

-

MARKING

MARKING

MARKING- Inkjet machines

- Transfers on multi support

- Marking by filling

- Labelling on all types of media

-

SEALING

Locations

Certifications