Business Overview

Tailor-made solutions for train interiors

On the strength of its experience in aircraft interiors design, the company created Satys Interiors which designs, manufactures and refurbishes train interiors by offering custom solutions for interiors. This activity includes floors, tables and partitions as well as refrigeration systems.

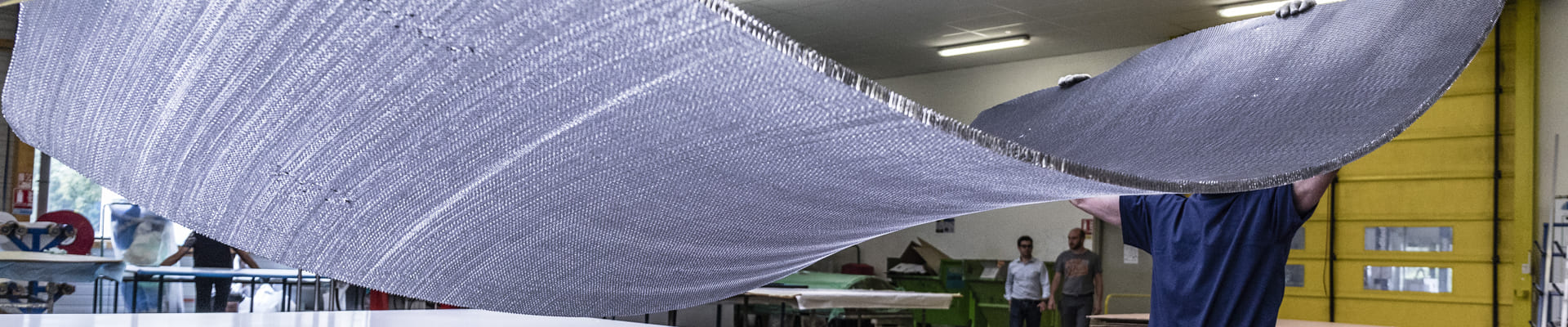

The production site in Boufféré (Vendée, France) has recently undergone significant investment to cut, manufacture press and assemble composite panels that are used in the production of floors or big partitions. In 2018, 50,000m2 of composite panels was manufactured in this factory.

Satys Interiors also works out of a site in Madrid where refrigeration systems are designed and assembled. They are used in dining cars and its main customers are Alstom, Hitachi and CAF.

Key

Figures

Services

Create value for the customers providing advanced solutions in the design, manufacture and installation of equipment, based on quality, safety, profitability and sustainability. Become the leading manufacture of galley systems and be recognized as a world leader in innovation, quality and service.

Key Products

Heating Flooring systems

Partitions & Doors

Ceilings

Galley systems

Bar, Dining Car and Catering onboard equipment

Interiors Furniture (staff area, driver cabin)

Lavatories

Underframe hatches

TSI PRM access ramps

Cooling and deep freezing systems

Lightweight roof for vehicles exterior

Bay Tables

Capabilities

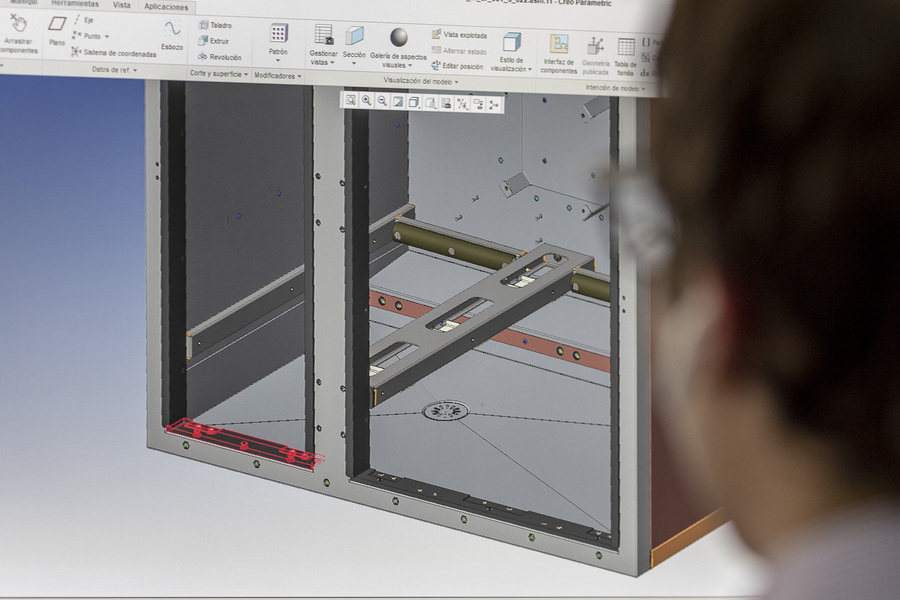

Engineering

- Project Management, Engineering and Design

- CAD stations (3D modeling, 2D drawings)

- Calculations based on FEA

- Expertise in acoustics, thermal insulation, cooling and electricity systems

- RAMS/LCC management

- Co-development process

Laboratory

- Full scale mechanical testing (static + dynamic)

- Climatic chamber testing

- Universal traction testing

- Fire & Smoke testing chamber

- Shock testing bay

- Laboratory pressing machine

- Fatigue & Ageing bench test

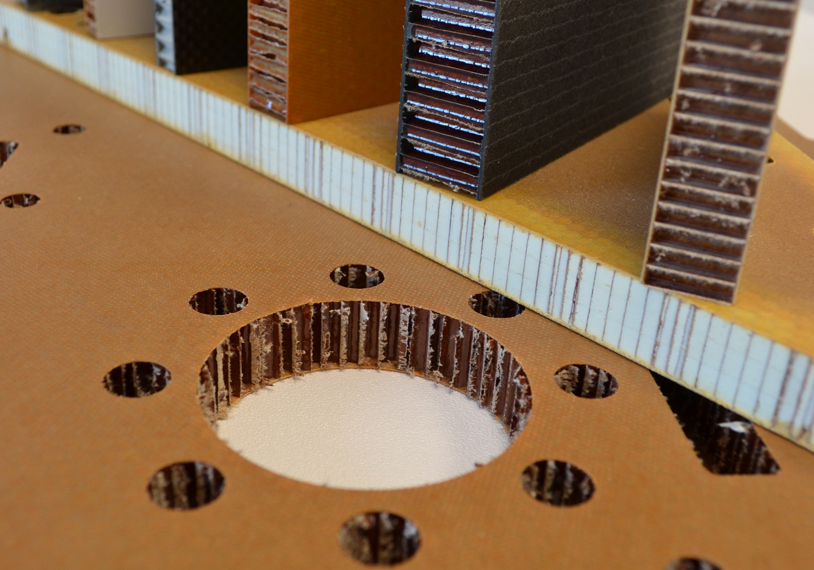

Composite panels

- The most suitable technology to make ready-to-assemble kits for train interiors

- Added value

- Mechanical and structural performances

- Very light weight solution

- Thermal & acoustic insultation improvement

- High finish level

- Ready to assemble kits quicky integrated into rail vehicules

- Compliance with fire-smoke-toxicity requirements